Understanding XR in Industry 4.0

Industry 4.0 marks a turning point in making industry systems smarter and more interconnected: it integrates digital and physical technologies like IoT, automation, and AI, into them.

And you’ve probably heard about Extended Reality (XR), the umbrella for Virtual Reality, Augmented Reality, and Mixed Reality. It isn’t an add-on. XR is one of the primary technologies making the industry system change possible.

XR has made a huge splash in Industry 4.0, and recent research shows how impactful it has become. For example, a 2023 study by Gattullo et al. points out that AR and VR are becoming a must-have in industrial settings. It makes sense — they improve productivity and enhance human-machine interactions (Gattullo et al., 2023).

Meanwhile, research by Azuma et al. (2024) focuses on how XR makes workspaces safer and training more effective in industrial environments.

One thing is clear: the integration of XR into Industry 4.0 closes the gap between what we imagine in digital simulations and what actually happens in the real world. Companies use XR to work smarter — it tightens up workflows, streamlines training, and improves safety measures.

The uniqueness of XR is in its immersive nature. It allows teams to make better decisions, monitor operations with pinpoint accuracy, and effectively collaborate, even if team members are on opposite sides of the planet.

XR Applications in Key Industrial Sectors

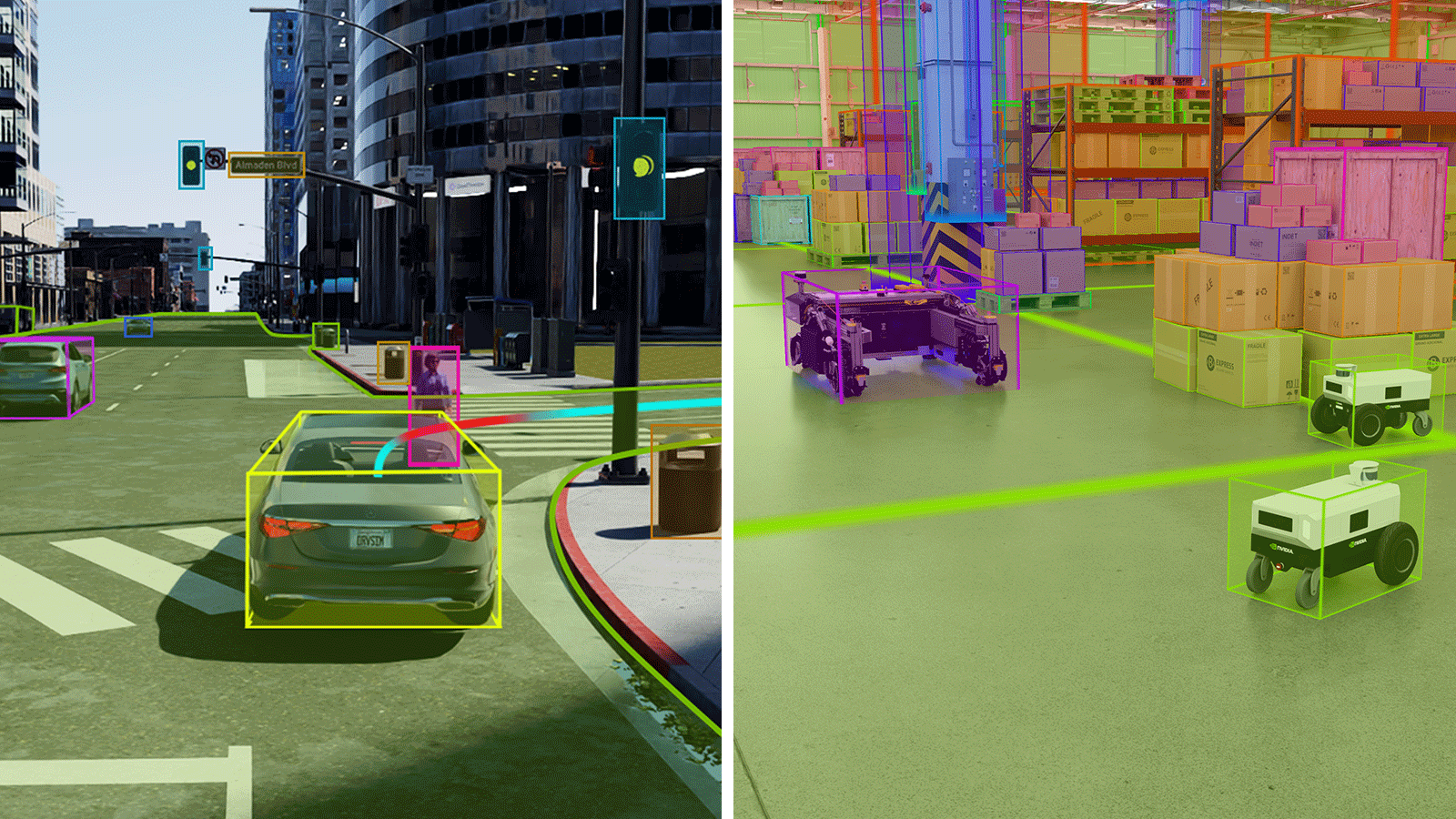

Manufacturing and Production One of the most significant uses of XR in Industry 4.0 is in manufacturing, where it enhances design, production, and quality control processes. Engineers now utilize digital twins, virtual prototypes, and AR-assisted assembly lines, to catch possible defects before production even starts.

Research by Mourtzis et al. (2024) shows how effective digital twin models powered by XR are in smart factories: for example, studies reveal that adopting XR-driven digital twins saves design cycle times by up to 40% and greatly speeds up product development. Besides, real-time monitoring with these tools has decreased system downtimes by 25% (Mourtzis et al., 2024).

Training and Workforce Development The use of XR in employee training has changed how industrial workers acquire knowledge and grow skills. Hands-on XR-based simulations allow them to practice in realistic settings without any of the risks tied to operating heavy machinery, whereas traditional training methods usually involve lengthy hours, high expenses, and the need to set aside physical equipment, disrupting operations.

A study published on ResearchGate titled ‘Immersive Virtual Reality Training in Industrial Settings: Effects on Memory Retention and Learning Outcomes’ offers interesting insights on XR’s use in workforce training. It was carried out by Jan Kubr, Alena Lochmannova, and Petr Horejsi, researchers from the University of West Bohemia in Pilsen, Czech Republic, specializing in industrial engineering and public health.

The study focused on fire suppression training to show how different levels of immersion in VR affect training for industrial safety procedures.

The findings were astounding. People trained in VR remembered 45% more information compared to those who went through traditional training. VR also led to a 35% jump in task accuracy and cut real-world errors by 50%. On top of that, companies using VR in their training programs noticed that new employees reached full productivity 25% faster.

The study uncovered a key insight: while high-immersion VR training improves short-term memory retention and operational efficiency, excessive immersion — for example, using both audio navigation and visual cues at the same time — can overwhelm learners and hurt their ability to absorb information. These results showed how important it is to find the right balance when creating VR training programs to ensure they’re truly effective.

XR-based simulations let industrial workers safely engage in realistic and hands-on scenarios without the hazards or costs of operating heavy machinery, changing the way they acquire new skills. Way better than sluggish, costly, and time-consuming traditional training methods that require physical equipment and significant downtime.

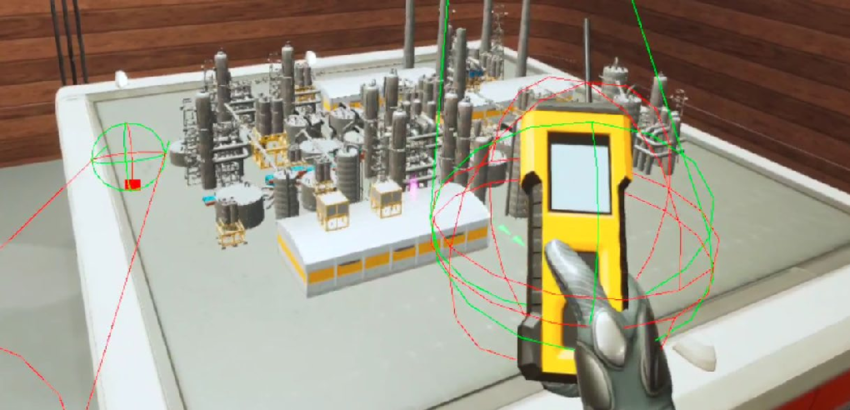

Maintenance and Remote Assistance XR is also transforming equipment maintenance and troubleshooting. In place of physical manuals, technicians using AR-powered smart glasses can view real-time schematics, follow guided diagnostics, and connect with remote experts, reducing downtime.

Recent research by Javier Gonzalez-Argote highlights how significantly AR-assisted maintenance has grown in the automotive industry. The study finds that AR, mostly mediated via portable devices, is widely used in maintenance, evaluation, diagnosis, repair, and inspection processes, improving work performance, productivity, and efficiency.

AR-based guidance in product assembly and disassembly has also been found to boost task performance by up to 30%, substantially improving accuracy and lowering human errors. These advancements are streamlining industrial maintenance workflows, reducing downtime and increasing operational efficiency across the board (González-Argote et al., 2024).

Industrial IMMERSIVE 2025: Advancing XR in Industry 4.0

At the Industrial IMMERSIVE Week 2025, top industry leaders came together to discuss the latest breakthroughs in XR technology for industrial use. One of the main topics of discussion was XR’s growing impact on workplace safety and immersive training environments.

During the event, Kevin O’Donovan, a prominent technology evangelist and co-chair of the Industrial Metaverse & Digital Twin committee at VRARA, interviewed Annie Eaton, a trailblazing XR developer and CEO of Futurus. She shared exciting details about a groundbreaking safety training initiative, saying:

“We have created a solution called XR Industrial, which has a collection of safety-themed lessons in VR … anything from hazards identification, like slips, trips, and falls, to pedestrian safety and interaction with mobile work equipment like forklifts or even autonomous vehicles in a manufacturing site.”

By letting workers practice handling high-risk scenarios in a risk-free virtual setting, this initiative shows how XR makes workplaces safer. No wonder more companies are beginning to see the value in using such simulations to improve safety across operations and avoid accidents.

Rethinking how manufacturing, training, and maintenance are done, extended reality is rapidly becoming necessary for Industry 4.0. The combination of rising academic study and practical experiences, like those shared during Industrial IMMERSIVE 2025, highlights how really strong this technology is.

XR will always play a big role in optimizing efficiency, protecting workers, and simplifying processes during this major change toward digital transformation as more industrial sectors embrace it.